欢迎进入连云港唯德复合材料设备有限公司官方网站!英文版

固定电话:0518-85703836 139-6139-5177

手机:139-61395-177

电话:0518-85280006

邮箱:247254853@qq.com

网址:http://www.wdfrp.com

地址:江苏省连云港市洪门工业园区新牛公路北

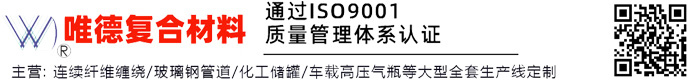

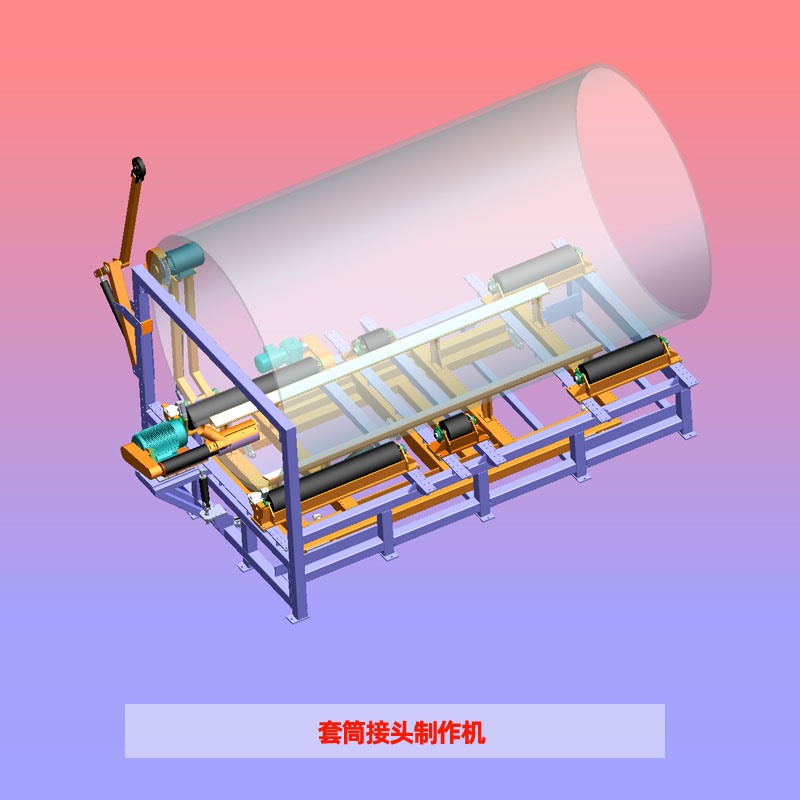

SMM套筒接头制作机介绍

设备功能、组成及原理:

设备功能

套筒接头制作机功能是连续管道生产线上辅助设备,用于连续缠绕管道套筒接头(RIKA接头)生产制作

设备组成

主要由管道旋转支架、自动进管装置、尺寸定位系统的磨削头装置、切割头、液压系统、电控系统、收尘系统等机构组成。

工作原理

将制作套筒接头毛坯管放置在管道旋转支架旋转,起动磨削头装置,。磨削头上成形刀具高速旋转,在液压油缸驱动下、在套筒接头毛坯管内壁进刀磨削。当进刀到一定尺寸后。磨削头上尺寸定位装置阻止继续进刀。这样在毛坯管内壁磨削成二道密封槽和定位槽。起动切割头按设定好宽度切割下已磨好的槽毛坯管头。完成的套筒接头制作,起动自动进管装置进行下一个套筒接头磨削。

Introduction to Sleeve Making Machine

Equipment function, composition and working principle:

Function--

As an auxiliary equipment in the continuous winding production line, Sleeve Making Machine is designed for the manufacturing of pipe sleeves (RIKA type).

Composition--

It mainly consists of pipe rotating support, automatic pipe-propelling device, grinding head device with sizing system, cutting heads, hydraulic system, electrical control system and dusting system.

Working principle--

Put the blank pipe for the sleeve coupling making onto the rotating support and make it rotate. Then, start the grinding head device. The form-cutter on grinding head spins at a high speed and, driven by the hydraulic cylinder, grinds on the inner pipe wall. After feeding to a certain size, sizing device equipped on the grinding head will stop the action. In this way, two sealing grooves and one locating groove will be formed in the inner wall of the blank pipe. Then, start the cutting head and cut the ground blank pipe according to the pre-setting width. After the sleeve’s being hoisted away, start the automatic pipe-propelling device to proceed the grinding of next sleeve coupling.