欢迎进入连云港唯德复合材料设备有限公司官方网站!英文版

固定电话:0518-85703836 139-6139-5177

手机:139-61395-177

电话:0518-85280006

邮箱:247254853@qq.com

网址:http://www.wdfrp.com

地址:江苏省连云港市洪门工业园区新牛公路北

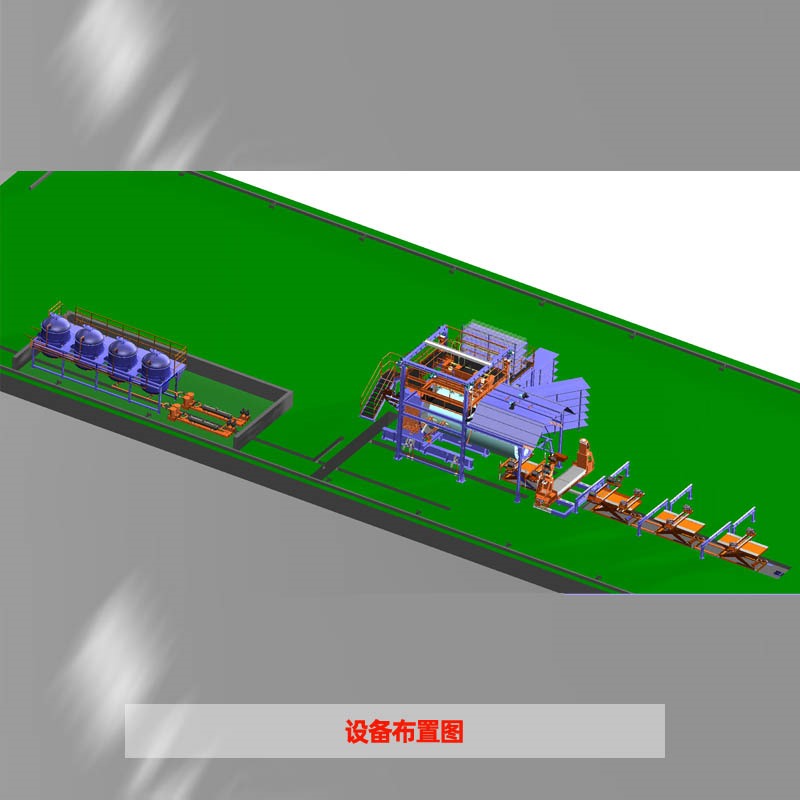

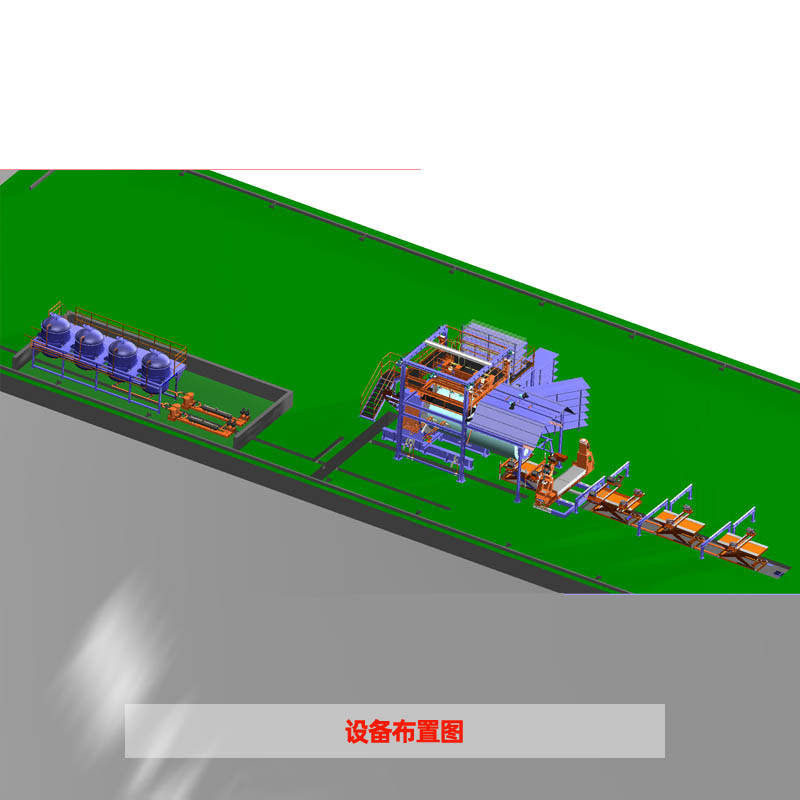

CFW系列连续管道缠绕机介绍

连续管道缠绕机设备功能、组成及原理:

设备功能:

CFW连续管道缠绕机是连续制管生产线上主要设备,用于连续缠绕管道制作。

设备组成:

其由主轴传动装置、总体框架、钢带推进装置、铝梁固定盘、钢带循环头、钢带循环导出头、钢带支撑铝梁 、钢带、内衬层切割纱装置、结构层切割纱装置、加砂装置、内衬层切割纱纱架、结构层切割纱纱架、结构层缠绕纱纱架、内衬层树脂搅拌淋胶装置、结构层树脂搅拌淋胶装置、红外线加热系统、缠聚脂薄膜架、缠表面毡架、缠外保护层架、内衬层气动压辊、结构层气动压辊、完成气动压辊、液压升降平台、在线切割、修整装置及收尘装置、 PLC 控制系统及电气控制系统等机构组成。

工作原理:

由铝梁、铝梁固定盘、钢带循环导出头、钢带循环头、闭环钢带组成的模具安装在缠绕机主传动装置。当缠绕机主传动装置带动模具旋转时,钢带会缠绕在沿铝梁固定盘一周均匀分布的铝梁上,同时在钢带推进装置作用下,钢带沿缠绕主轴轴向移动,主轴每旋转一周钢带推进装置将钢带沿轴向推进一个钢带宽度。当钢带沿轴向方向推进到铝梁尾部时,钢带进入钢带循环导出头、钢带循环头,钢带被导入缠绕机主传动装置的主轴(中空轴)内,经钢带缠绕导向装置返回到缠绕的始点。这样钢带形成缠绕、推进、导出、导入、再缠绕循环过程。当钢带形成缠绕循环运动时,在钢带上缠绕一层聚脂薄膜、表面毡。同时上方的内衬淋胶装置,结构层淋胶装置,往钢带上淋适量树脂。内衬层切割纱装置、结构层切割纱装置往钢带上洒上适量短切纤维。加砂装置往钢带上洒上适量石英砂,缠绕纱架提供环向缠绕纤维纱。当钢带上环向纤维、短切纤维、树脂、石英砂在滚压装置作用下充分混合、浸透。在钢带作用下沿主轴轴向前进,进入红外加热区,进行加热固化同时沿主轴轴向继续前进并离开钢带模具,液压升降平台按序升起,平台上托辊托起固化好管道。管道具有一定长度后在线切割、修整装置起动对管道进行切割、修整。从而完成管道制作,内衬切割纱量、结构层切割纱量、缠绕纱量、石英砂量、树脂量是预先设定好的并由PLC控制。树脂温度、石英砂温度也由PLC控制。

Introduction to CFW Continuous Pipe Filament Winding Machine

Equipment function, composition and working principle:

Function--

As the main equipment in the production line, this CFW 3000 continuous filament winding machine is designed for the GRP pipe manufacturing.

Composition--

It mainly consists of mandrel driving device, overall frame, steel band pusher, beam cam disc, band circulating head, band exit head, beam for band supporting, steel band, liner chopper devices for liner and structure, sand feeding device, chopped roving shelf for liner and structure, hoop roving shelf for liner and structure, resin mixing and spraying devices for liner and structure , infrared heating system, mylar winder, surface veil winder, external layer winder, pneumatic rollers for liner and structure, finishing pneumatic roller, Hydraulic lifting table, online cutting & grinding device, dust collector, PLC control system, electrical control system, etc.

Working Principle--

The main transmission of the winding machine is assembled with mould consisting of cam disc, band exit head, band circulating head, beams for band supporting and closed-loop steel band.

Once the mould rotates with the transmission, steel band winds on the beams distributed around the circle of cam disc and moves in the axial way under the impetus of pushers. Band will be pushed forward at one band width with every complete revolution of the mandrel. When it arrives the rear end of the beam, steel band will be led into mandrel’s hallow tube via exit head and circulating head, and then return to the very starting point. In this way, steel band forms a circulation process of winding, pushing forward, leading out, leading in and rewinding.

Wind the mylar and surface veil onto the band as it forms the winding cyclic movement. And, simultaneously, onto the band, spray resin through spraying device for liner layer and structure upward side, spread chopped roving via chopper devices for liner layer and structural layer, feed sand by sand feeding device, and wind hoop roving from the roving shelf. After the hoop roving, chopper, resin and sand on the band are completely mixed and impregnated with the effect of pneumatic roller, it moves forward with band in the axial way into the infrared heating area to be cured and then moves on until leave the band mould. Hydraulic lift table will rise sequentially and the rollers on the table support the cured pipe. Pipe will be cut after it reaches a certain length and both ends are trimmed by online cutting and trimming devices. In this way, the production of a pipe is done. The amount of chopped roving for liner layer and structural layer, hoop roving, sand as well as resin are preset and controlled by PLC which also controls the temperature of resin and sand.