Welcome to the official website of Lianyungang Weide Composite Equipment Co., Ltd!中文版

fixed telephone:0518-85703836 139-6139-5177

Mr Guo: 139-61395-177

Telephone:0518-85280006

mail:247254853@qq.com

Web:http://www.wdfrp.com

address:Xinniu Highway North, Hongmen Industrial Park, Lianyungang City, Jiangsu Province

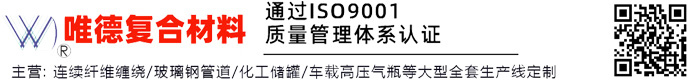

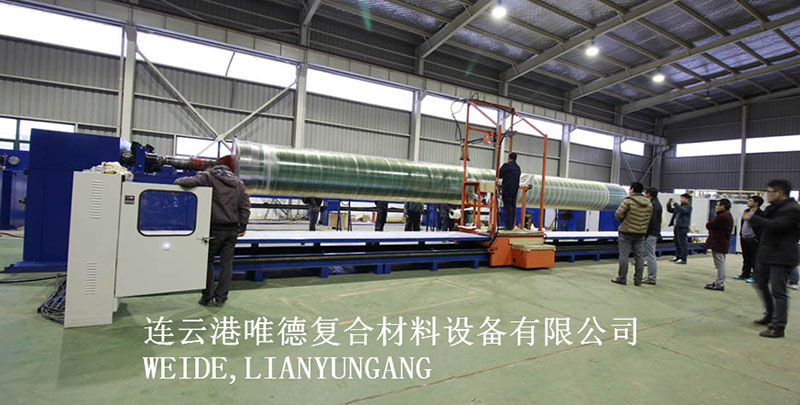

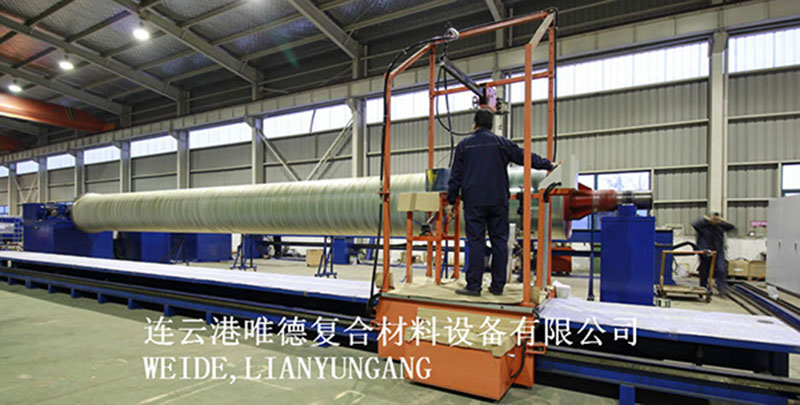

Dis Continuous Production Line

SPECIFICATION:

1.DN200-1000*12000 Discontinuous Sand Feeding FRP Pipe Production Line

2.DN200-1600*12000 Discontinuous Sand Feeding FRP Pipe Production Line

3.DN200-2000*12000 Discontinuous Sand Feeding FRP Pipe Production Line

4.DN200-2600*12000 Discontinuous Sand Feeding FRP Pipe Production Line

5.DN200-3000*12000 Discontinuous Sand Feeding FRP Pipe Production Line

6.DN3000-4000*12000 Discontinuous Sand Feeding FRP Pipe Production Line

COMPOSITION:

LINER MACHINE

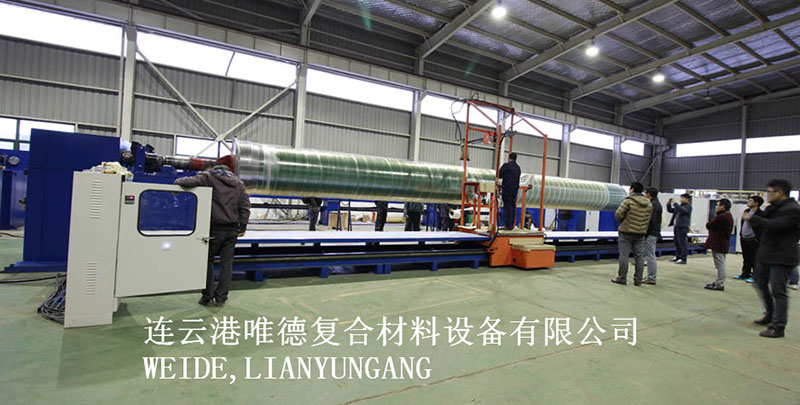

WINDING MACHINE

CURING MACHINE

DEMOULDING MACHINE

TRIMMING MACHIEN

HYDROSTATIC TESTING MACHINE

RESIN MIXING AND TRANSPORT SYSTEM

SCOPE OF APPLICATION:

1.Sand Feeding FRP Pipe of DN200-1000MM, L≤12000mm

2.Sand Feeding FRP Pipe of DN200-1600MM, L≤12000mm

3.Sand Feeding FRP Pipe of DN200-2000MM, L≤12000mm

4.Sand Feeding FRP Pipe of DN200-2600MM, L≤12000mm

5.Sand Feeding FRP Pipe of DN200-3000MM, L≤12000mm

6.Sand Feeding FRP Pipe of DN200-4000MM, L≤12000mm

PARAMETERS:

1.Product DN: Ф200mm-Ф1000mm

Ф200mm-Ф1600mm

Ф200mm-Ф2000mm

Ф200mm-Ф2600mm

Ф200mm-Ф3000mm

Ф3000mm-Ф4000mm

2.Product Length:12000mm

3.Winding Angle:≥45°≤90°

4.Fiber-drawing Speed:≤110m/min

5.Mandrel Speed: Two output speeds for each mandrel on the basis of different winding diameters

6.Sand Feeding Mode: Pre-mixed Sand Feeding or Laminated Sand Feeding

7.Equipment Total Power: pre-mixed sand feeding--205-240±5KW;

laminated sand feeding--187-222±5KW

8.Requirement of installation space:W=24000mm,L=84000mm

9.Resin content of sand feeding layer is controlled by PLC